[ad_1]

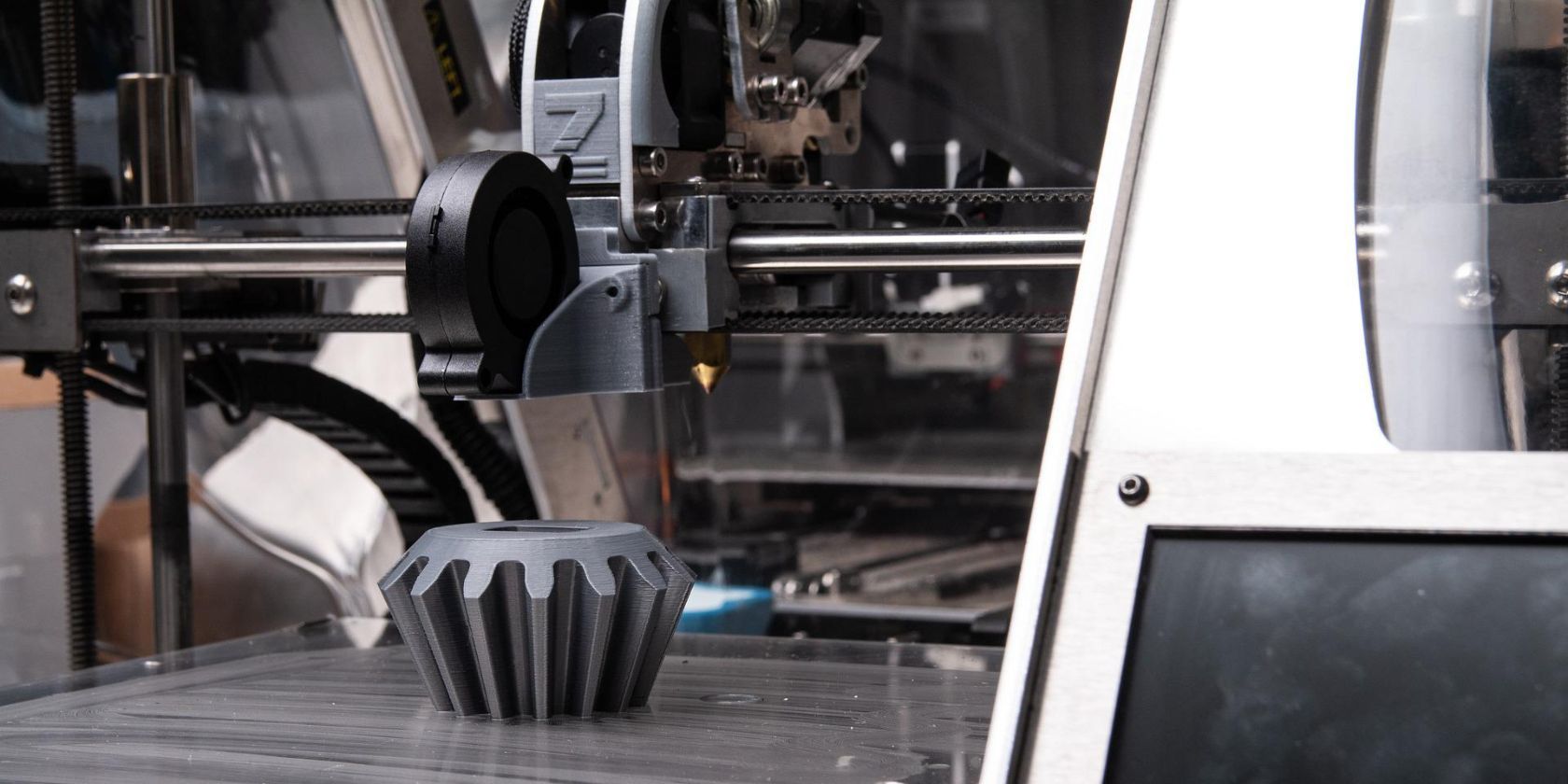

As any skilled 3D printing fanatic will let you know, slicer settings make a giant distinction when working with completely different supplies. ABS and PLA filaments share related properties, however you continue to want to regulate your settings to get the most effective outcomes with every materials.

To present you an concept of the most effective slicer settings for PLA and ABS, this text will take you thru all essentially the most essential settings. You’ll have to hone these settings to match each your 3D printer and filament. This course of is way simpler when you’ve a head begin.

What Is the Distinction Between PLA and ABS 3D Printer Filament?

There are a number of key variations between PLA and ABS that you simply want to pay attention to earlier than you begin printing with them. PLA is usually thought to be simpler to print with, although it isn’t as sturdy or sturdy as ABS. However what else is completely different?

PLA (Polylactic Acid)

PLA is a well-liked thermoplastic that’s derived from plant starches. Whereas this materials isn’t as sturdy as different 3D printer filaments, this can be very simple to print with and suffers little from points like warping. PLA can also be nice at adhering to nearly any construct floor.

ABS (Acrylonitrile Butadiene Styrene)

ABS is produced from a mix of three completely different plastics/rubbers. It’s stronger than PLA, but additionally tougher to print with. ABS likes to warp, requires greater temperatures than PLA, and may also pose well being dangers when misused.

It is price taking the time to study completely different 3D printer filament varieties so that you could additionally select the best choice in your initiatives.

Nozzle & Mattress Temperature

FDM 3D printers use warmth to melt filament supplies in order that they are often formed and bonded collectively. ABS and PLA have very completely different nozzle and mattress temperature necessities; ABS prefers it hotter, whereas PLA works properly in cooler circumstances.

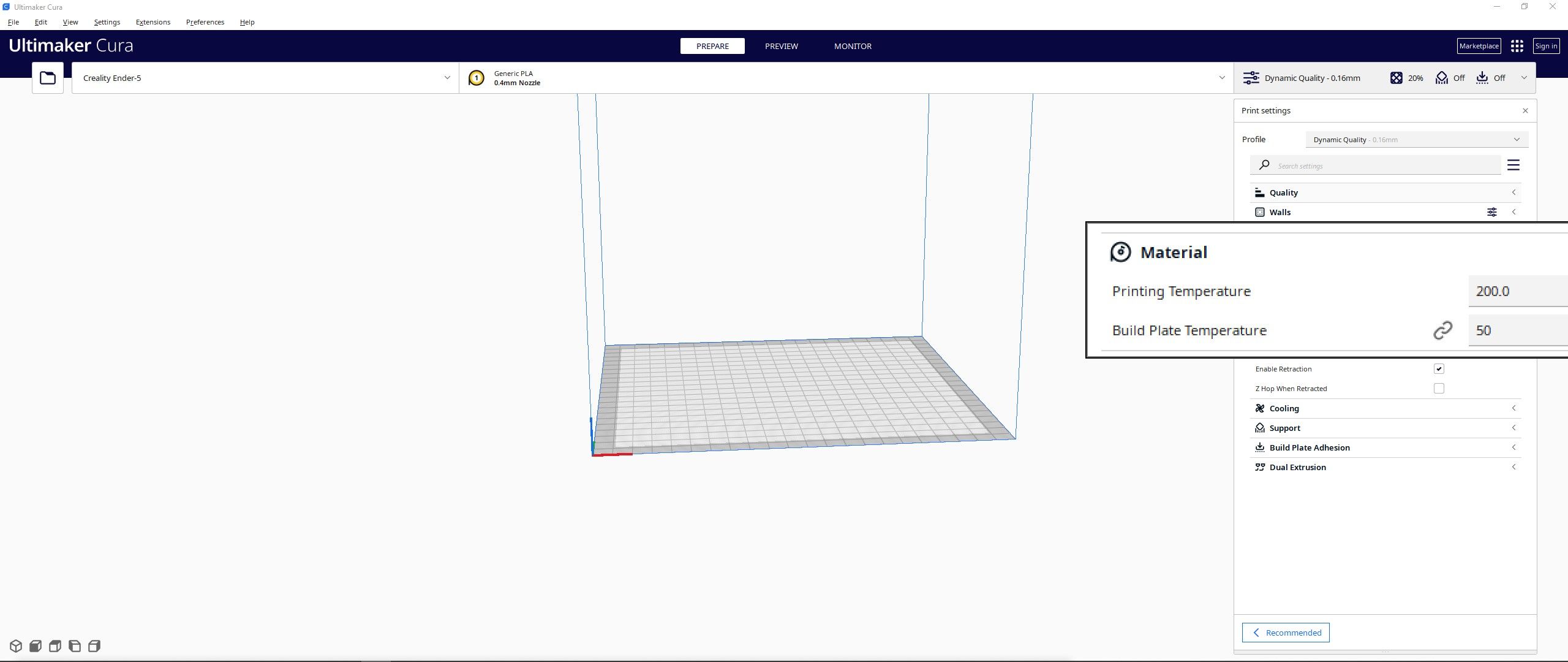

PLA 3D Printer Nozzle & Construct Floor Temperatures

You may print PLA with out a heated construct floor, so long as it has a texture that the plastic will adhere to. Regardless of this, PLA advantages from a mattress temperature between 50°C and 60°C.

Your construct floor additionally must be stage to work correctly. Studying find out how to stage your 3D printer mattress takes time and persistence, however the outcomes are properly price it.

The very best nozzle temperature for PLA often ranges between 200°C and 215°C. You need to use temperature tower calibration 3D fashions to seek out the most effective printing temperature in your printer.

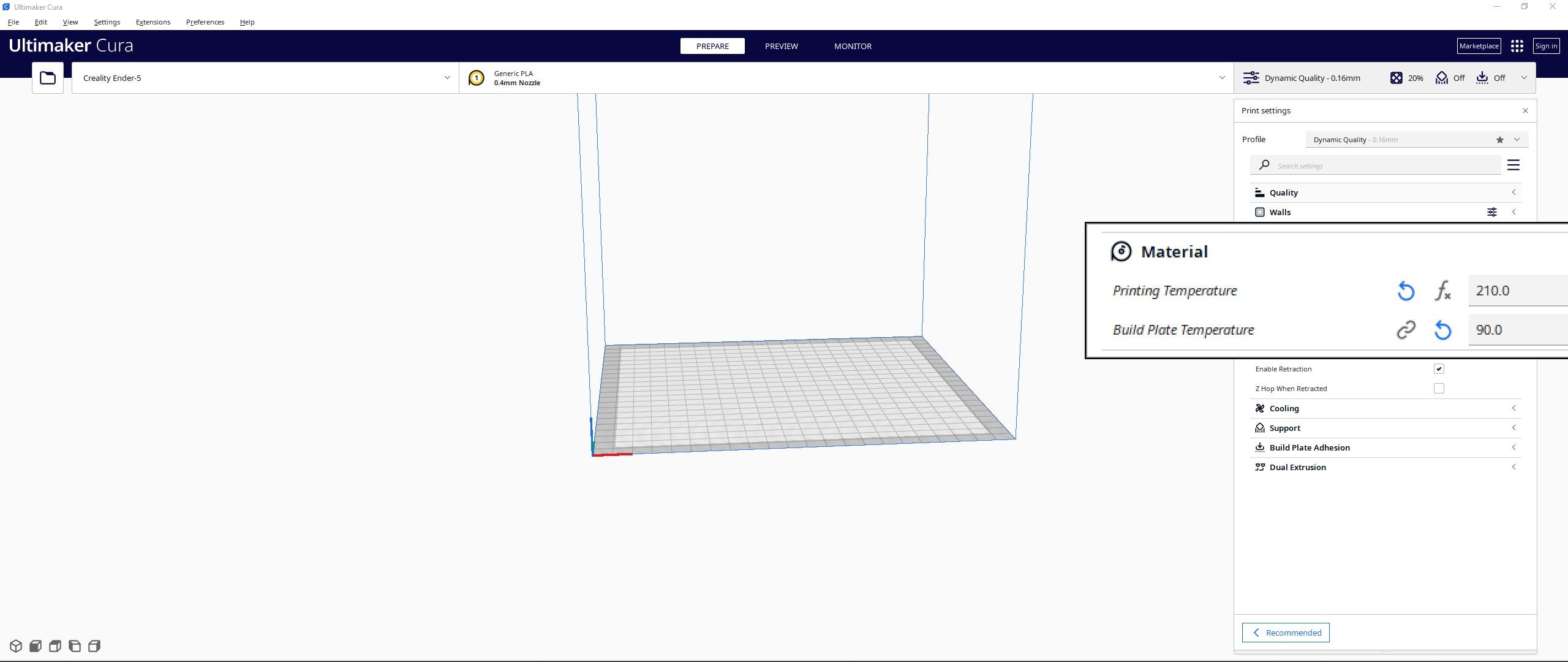

ABS 3D Printer Nozzle & Construct Floor Temperatures

It’s nearly unattainable to print ABS with out a heated mattress, as this materials suffers from severe warping when uncovered to completely different temperatures. Utilizing a heated mattress between 90°C and 110°C is an efficient place to begin with ABS.

ABS has the next melting level than PLA. It’s best to intention between 210°C and 250°C earlier than you begin experimenting with ABS 3D printing temperatures.

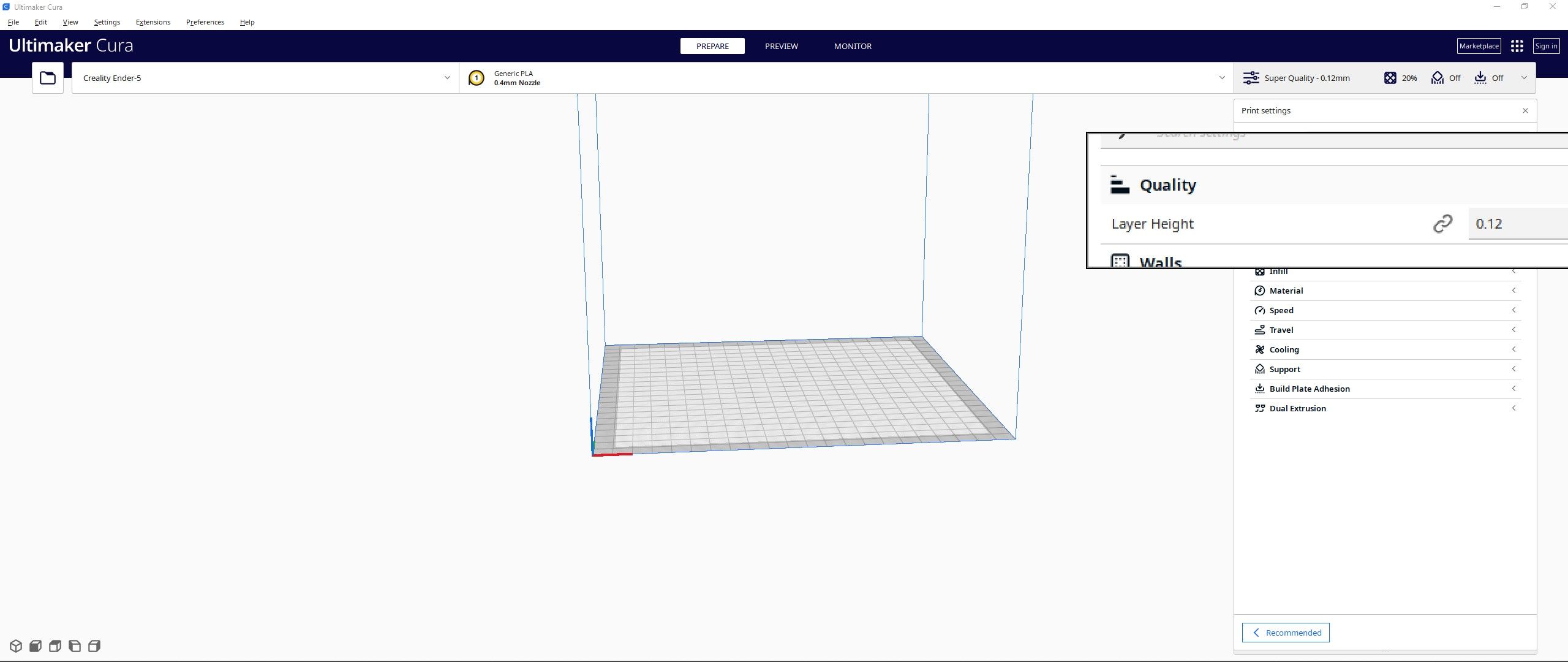

Layer Top

As its identify suggests, layer peak is the peak of every of the layers created by your 3D printer. Each PLA and ABS are extraordinarily forgiving in terms of layer peak, and you must select this setting based mostly on the dimensions of your nozzle and the standard you need. For instance, a 0.4mm nozzle ought to be used for layer heights between 0.12mm and 0.28mm.

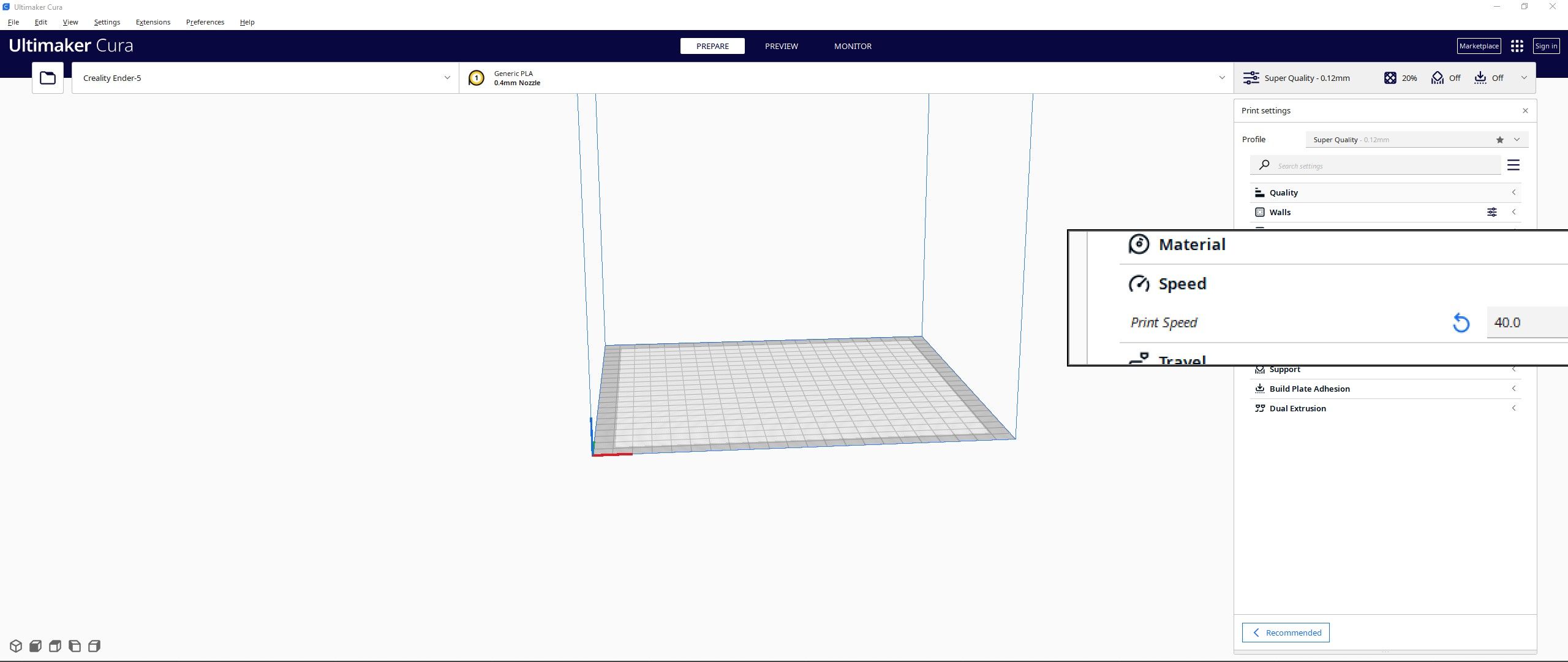

Motion Pace

Your 3D printer extruder and hotend transfer round to create your 3D prints, and the pace of those actions must be exact. Each PLA and ABS print properly with motion speeds between 40mm/s and 60mm/s. Going too slowly may cause over-extrusion, whereas going too quick may cause under-extrusion and poor-quality prints.

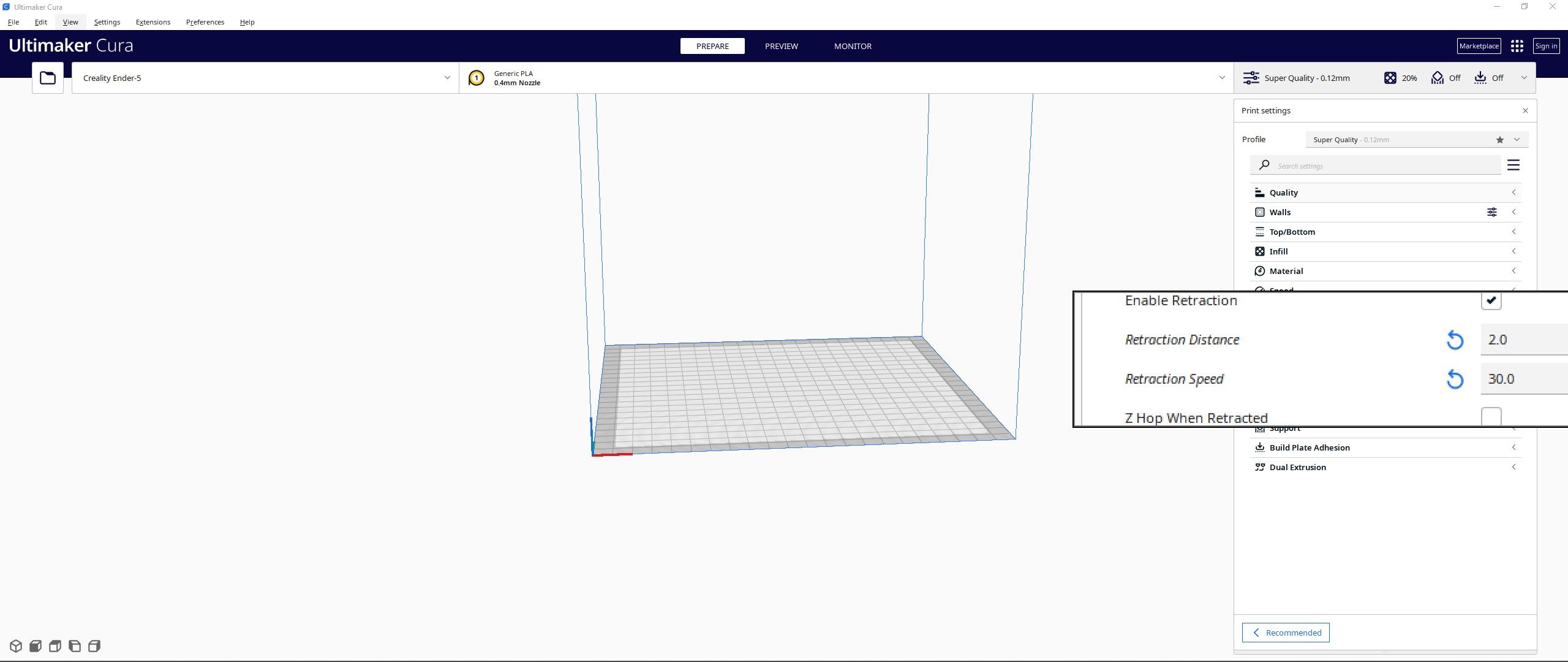

Retraction Pace & Distance

Many 3D printers are capable of retract filaments to cease extrusion. This makes it potential for the hotend to maneuver round with out leaving strings of plastic behind it. Each PLA and ABS work properly with a retraction pace between 40mm/s and 60mm/s and a restriction distance between 0.5mm and 1mm for direct-drive extruders, and between 30mm/s and 50mm/s with a 2mm distance for Bowden setups.

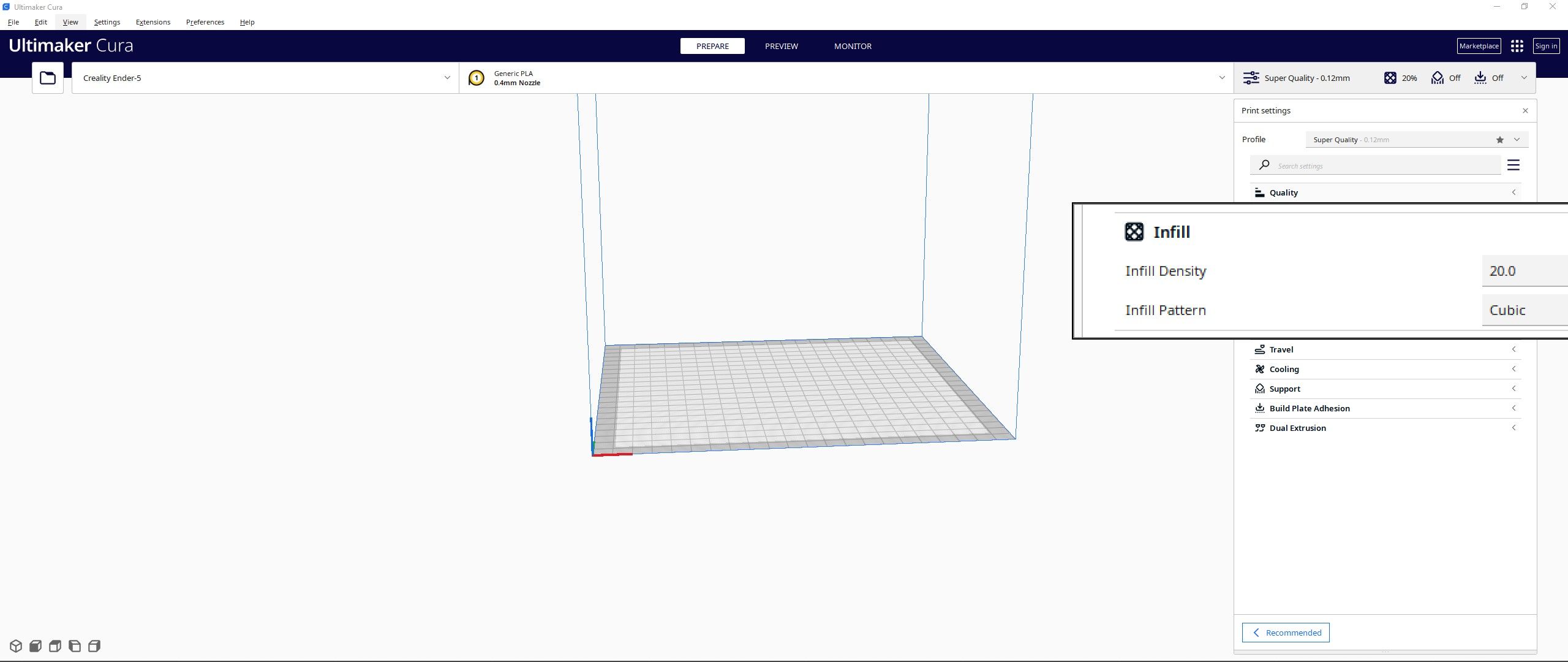

Infill Kind & Density

It’s uncommon to print a stable object with an FDM printer. As a substitute, infill patterns fill the house inside the item, saving weight, filament, and time. Each ABS and PLA work finest with at the very least 10% infill density, however you’ll be able to push this as much as 30% for a stronger object. Past 30% infill density you received’t get a big energy enhance normally.

Many slicer applications let you select from a spread of various infill patterns/varieties. The sample you select can impression the energy of your prints and the time it takes to 3D print them, however the distinction is simply too small for a lot of customers to note.

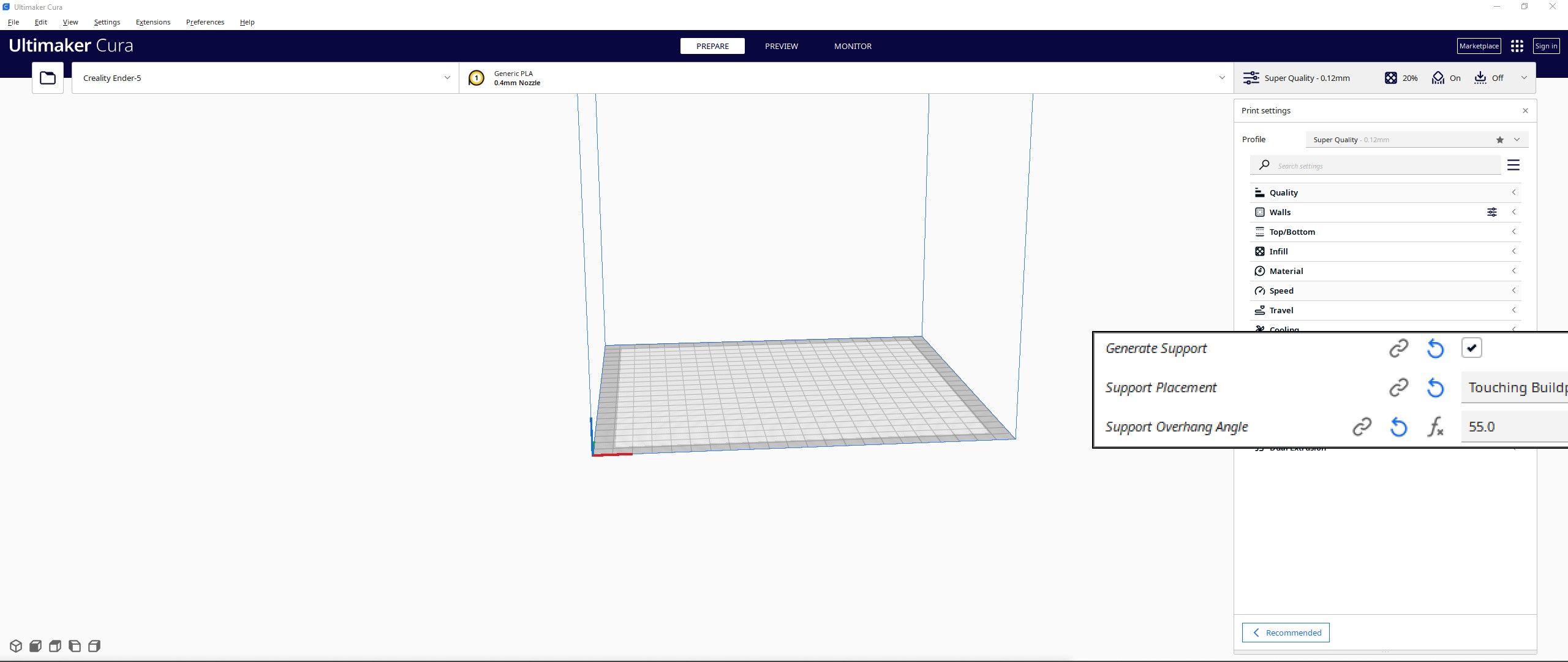

Assist Kind & Materials

Helps are a significant a part of 3D printing, making it potential to print objects with overhangs that will in any other case be within the open air. PLA and ABS work properly with each tree-like helps and common tower helps. The overhang angle you select dictates how steep an overhang must be earlier than helps are generated. 0 levels will help all overhangs, whereas 90 levels will help no overhangs; 55 levels is an efficient place to begin. It is price preserving in thoughts that completely different slicers deal with helps in their very own methods.

It’s at all times price eager about the supplies you utilize in your 3D-printed helps. Multi-material prints work with water-soluble filaments that disappear when they’re soaked in water. That is nice for sturdy supplies like ABS and supplies with good adhesion, like PLA.

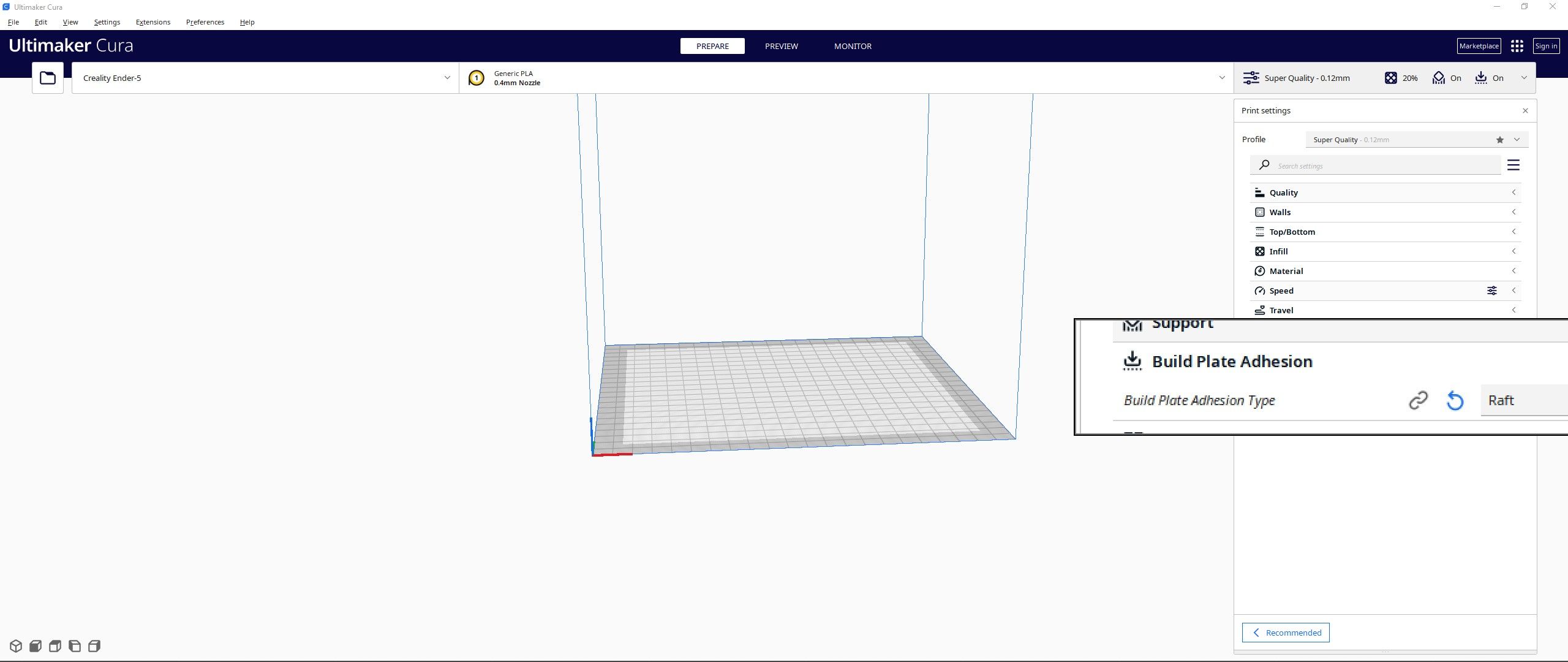

3D Print Additions

Most slicer instruments are capable of embrace a spread of additives to your 3D prints. This contains rafts and brims to assist with floor adhesion, together with different instruments like wiping towers and partitions. Rafts present the right base for a lot of PLA 3D prints, particularly in case your slicer software program turns up the warmth for the primary few layers. This can provide you management over the small quantity of warping that may happen with PLA.

ABS warps way more readily than PLA, and a raft can serve to make this worse in case your mattress isn’t leveled appropriately. Brims can show significantly better for ABS than rafts, as they anchor every nook and spherical it off. This spreads the stress attributable to warping and makes it simpler for the item to stay on the print mattress.

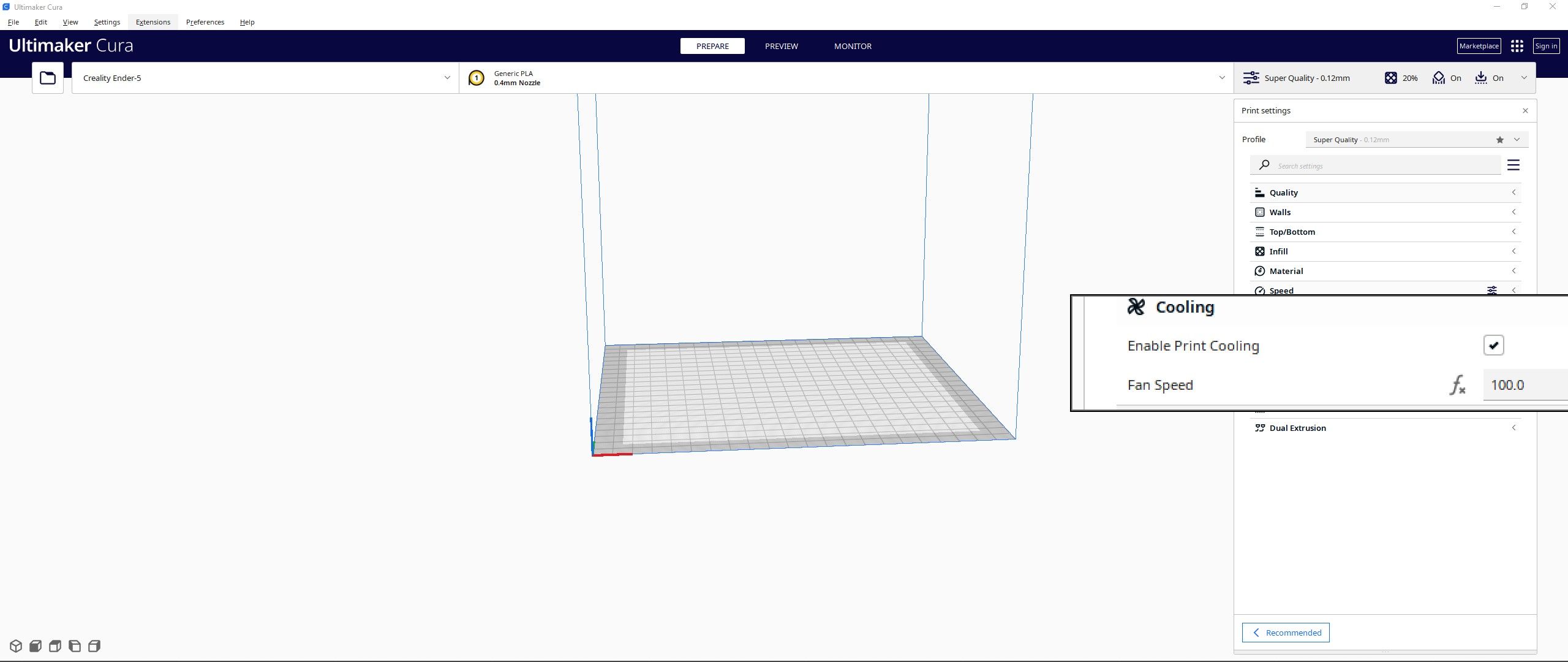

3D Printer & Half Cooling

PLA and ABS are related, however their cooling wants are drastically completely different. PLA advantages from being cooled as quickly because it comes out of the nozzle, however ABS prefers no half cooling in any respect. Utilizing half cooling with ABS will increase the prospect of warping and poor layer adhesion, however enclosure cooling remains to be a good suggestion.

Basic 3D Printer Construction (Beds & Enclosures)

PLA is an unimaginable materials that’s appropriate for nearly any FDM 3D printer. Glass, steel, and taped construct surfaces can all present wonderful outcomes, and also you don’t want any kind of enclosure to print with this materials.

ABS, then again, is a really completely different story. Enclosures are important for ABS 3D printing. Not solely do they defend the print as it’s made, however in addition they lure warmth and cut back the prospect of warping because the half cools down. Fortunately, you may make your individual 3D printer enclosure with relative ease in the event you observe a information.

3D Print With ABS and PLA

As two of the most typical 3D printable supplies available on the market, it is smart that PLA and ABS are well-tested. Even so, you must at all times work to dial in your printer to just be sure you are selecting the most effective settings in your filament model and the 3D object itself.

[ad_2]